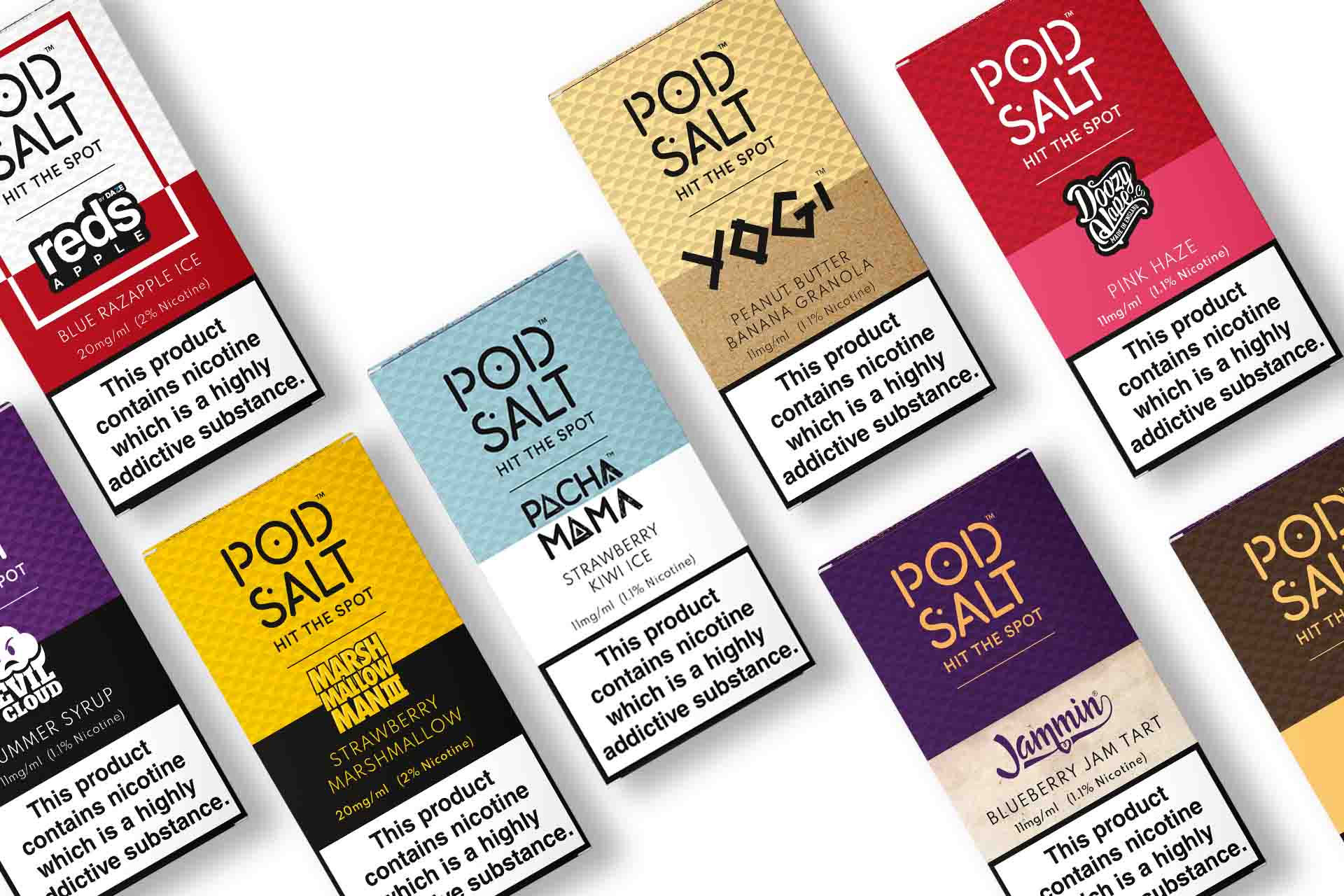

Packaging is more than just a means for holding products; it's an essential aspect of branding, consumer engagement, and sustainability. In the dynamic world of vaping, packaging trends evolve to captivate an audience that is not just looking for high-quality...