Protecting your brand and recipe is of the utmost importance to us which is why we employ strict procedures to ensure your brand equity remains protected. We wish to instil the utmost confidence in our customers when handling their brands, to make sure that products are not only safe and high-quality but also secure.

How do we protect brand equity?

In an industry ruled by flavours, trying to create new and unique flavour E-Liquids and vape devices, or creating higher quality flavours, is key. The last thing you want after all your hard work of establishing your brand’s flavours is to lose them. To ensure that brands’ flavours remain protected we established a series of procedures.

When our lab receives the flavour profile for your E-Liquids, they gather the necessary ingredients to make the batch of vape juice. However, each flavour ingredient is given a codename. When is orange not orange? When you are protecting a brand’s equity! To ensure that recipes remain confidential, those that process and produce the E-Liquids only ever see the codename version of flavour ingredients. This allows us to have fewer eyes on the actual recipe.

Once the flavour has been developed, you can then sample the flavours with our Flavour Specialist. Tweak and update the flavours and strengths depending on what you want to achieve or get ready to bulk produce it – we’re with you every step of the way.

Protecting your brand name

Ensuring brand equity doesn’t just stop at your flavour recipes. Making sure that your brand name continues to promote consistent quality is another one of our priorities. Mistakes can not only be costly in raw materials but in name. That’s why we employ a huge range of quality control procedures at every step of the process. Thanks to our training solidified by our GMP and ISO certification, we can produce high-quality products in safe environments to ensure the safety of your products.

Throughout the flavour creation process, your E-liquids go through a series of quality checks before mixing, before lab testing and after batch testing. Every step of the way there are quality checks to ensure zero errors. Up until the products leave our door, we can offer full batch-tracing at every step so that if errors do occur, we are able to quickly and efficiently go back to the source and correct it.

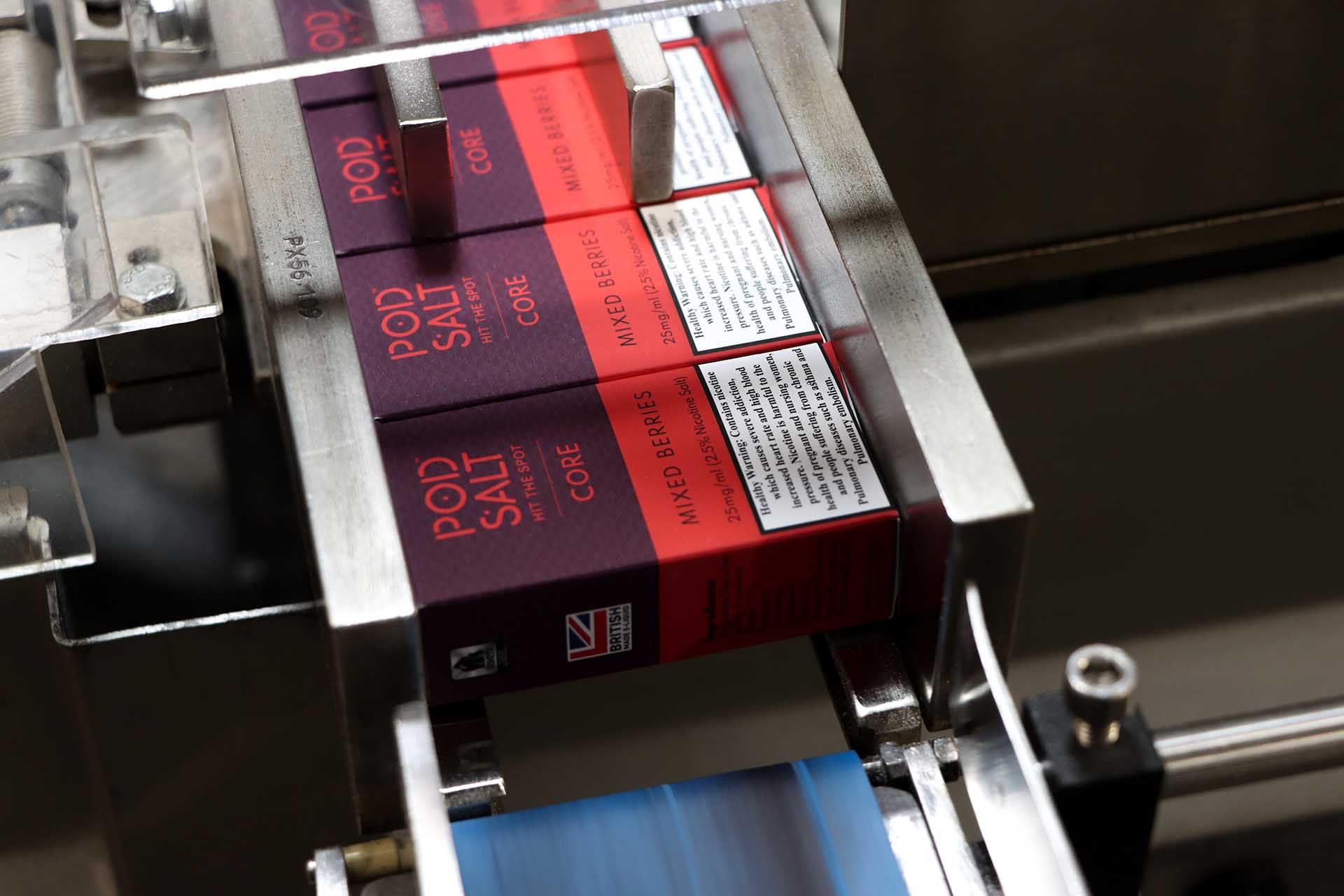

Our production warehouse is fully equipped to allow us to fulfil your bottling, filling and labelling requirements, as well as flavour development and E-Liquid manufacture. As one of the leading UK E-Liquid manufacturers, we are also able to ensure that compliance, quality, and safety is achieved for every product we produce.

If you would like to talk to us about manufacturing your latest product or kickstarting your own brand, contact us now.